Flat glass

Today, Planes glass is essentially produced using two processes: the clear-glass mirror glass in the float glass process and the opaque cast glass in the rolling process. Both main types of flat glass are processed in different processes into functional glasses and combined with each other. The third method of lesser importance is the drawing method (Fourcault method), in which sheet glass (window glass) is produced.

Available float glass thicknesses are: 2,3,4,5,6,8,10,12,15 and 19 mm other glass thicknesses on request.

Float glass can be obtained in the colors Parsol Green, Gray or Blue and in their tints. As a white glass it is used in museums, so as not to influence the view of the exhibits. It is also available as a low-reflection or UV-filtering glass.

Float glass

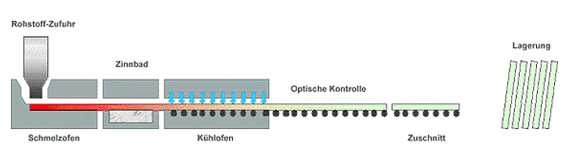

Float glass (formerly mirror glass) is a plan clear soda lime glass. In the meantime, modern float glass production has replaced virtually all earlier production methods for flat glass. The name "Float" refers to the actual manufacturing principle. To produce the raw materials are melted as a batch in the furnace at a temperature of 1500 ° C. The molten glass is passed under a protective gas atmosphere via a narrow channel to a liquid, flat tin bath. The temperature of the melt is about 1000 ° C when entering the tin bath (float bath). The lighter melt floats on the surface of the liquid metal and spreads out. As a result of the surface tension of the molten glass and the flat surface of the tin bath, an absolutely plane-parallel glass ribbon is naturally formed. The speed of the rollers in the cooling area is used to set the thickness of the glass. In the production of thinner glasses (up to about 2 mm thickness), a higher speed of the rollers is driven with thicker glasses this is reduced (theoretically about 35 mm thickness possible). In the cooling channel on the subsequent transport section, the glass cools from approx. 600 ° C down to room temperature. After cooling, the glass ribbon is checked for defects by means of a laser and cut into glass sheets. In modern systems, up to 6 tons of glass can be produced daily in thicknesses from 2 to 19 mm and maximum tape dimensions of 320 cm x 600 cm. Float glass is the basic product for further processing into toughened glass (ESG, TVG), laminated glass and insulating glass.

Cast glass

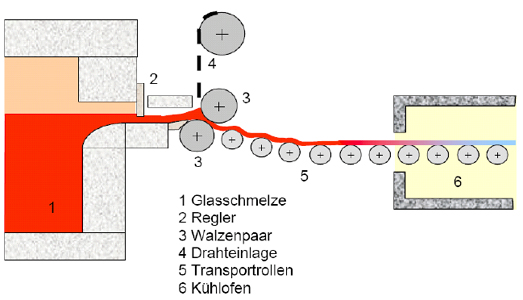

In the production of cast glass, the glass melt is either cast discontinuously on a plate and rolled or formed after continuous leakage from a melting furnace between rollers, for. B. profile glass. The rolling process leads to a rough surface of the glass, which results in a lower strength compared to the float glass. Cast glass is translucent, but opaque. The characteristic feature of all cast glass is the more or less pronounced ornamentation of the surface. This ornamentation can be either on both sides and is transferred by rollers with ornamented surfaces on the glass. In the production of wired glass, a wire insert is rolled into the melt. The wire mesh does not serve as a reinforcement of the glass to increase the load capacity, on the contrary, the tensile strength is still reduced. The wire net only has the task of holding the broken glass together in the event of mechanical destruction of the pane. Since the coefficient of thermal expansion of glass is about 1/3 less than that of steel, wire glass reacts more sensitively to thermal stress than float glass.

Production process of cast glass with wire insert.

An overview of ornamental glasses, with pictures and photos can be found at Ornamental glass.

Pulling glass

This includes various methods for glass production by means of mechanical devices in the drawing process of continuously produced table glasses. Belgian engineer Fourcault has developed the first sheet glass drawing process. Part of the window glass is still manufactured today in Fourcault plants. This, however, mainly in Eastern Europe or in developing countries. Common to all drawn glass types is the more or less pronounced optical restlessness caused by the drawing process, which at the same time represents the strongest characteristic. The thickness of the glass is varied only by changing the pulling speed. Slow pulling results in thick glass, fast pulling provides thin glass. Drawing glass today is largely replaced by float glass and is only offered in small quantities. The drawing process is used in Western Europe only for thin glass (0.2 mm - 2 mm).

For your repair, project plans and news to us you can use our contact form or email us at info@glastechnik-berlin.de.

Glastechnik-Berlin, Dove Str.7, 10587 Berlin

Tel.: 030/69817228

© 2006-2019 Glastechnik-Berlin

Share this page with:

![]()

![]()